Description

|

| |

|

| Downloads |

|

Leaflet – Turbolite Brochure |

The Turbolite is a high powered compressed air driven lamp developed from the well known Wolf Airturbo and is certified for use in Zones 1 and 2 hazardous areas, commonly used in the oil and petrochemicals industries, for tank cleaning and pipeline inspections, offering a safer alternative to low voltage lighting in dangerously wet conditions as well as where flammable gases and vapours can accumulate in confined spaces.

The Turbolite A-TL44 has a Bay Light fitting comprising a ball glass and protective polycarbonate dome to provide all-round general purpose illumination and a hook provides for suspension of the lamp in the working area or for simple fastening to a folding tripod. The Turbolite A-TL45 has a reflector head fitting for direct illumination with a polished or matt reflector giving the option of a concentrated narrow beam or diffused wide angle illumination.

The housings are cast brass, a spark free material, and the safety hook is also brass, but forged for extra strength and all external parts are nickel plated. Internal components are of durable design making the products suitable for use in the harshest industrial environments. A clean dry air supply is a condition of certification and essential for the efficient running of these lamps, otherwise contamination will deposit into the inside of the lens, reducing illumination levels. Suitable air-line filters can be supplied. Another mandatory requirement is the use of anti-static hose, to prevent the generation of unsafe levels of static electricity.

The 24 volt 250 watt tungsten halogen bulb is available in two types offering a choice of 6,000 lumens for 2,000 hours or 9,000 lumens for 200 hours. Lamps are routinely run in, tested and set to the necessary output prior to despatch and are simple and easy to maintain.

Technical Specifications

Light Output

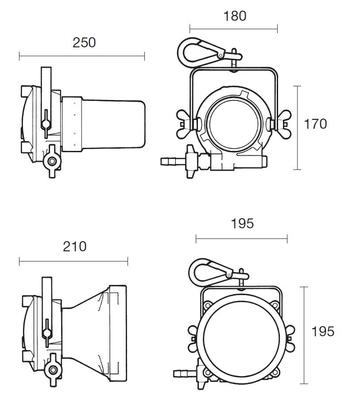

Product Dimensions

A-TL44 – Ball Glass

250w with ball glass for all round illumination

Peak luminous intensity at 2.5m radius 70lux

A-TL45 – Polished Reflector

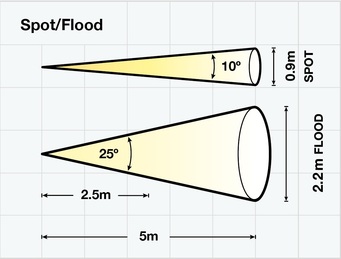

Spot beam (approx 10°)

Peak luminous intensity at 5m 2000lux

A-TL45 – Matt Reflector

Flood beam (approx 25°)

Peak luminous intensity at 5m 950lux

| Product Reference | A-TL44 | A-TL45 | |||

|---|---|---|---|---|---|

| Product Description | Safety Bay Light Compressed Air Powered | Safety Flood Light Compressed Air Powered |

|||

| Code | Ex s II T4 | ||||

| Apparatus Standards | SFA 3009:1972 | ||||

| Type of Protection | “s” special protection | ||||

| Area of Classification (Gas) | Zones 1 and 2, Gas Groups IIA, IIB, IIC | ||||

| Temp. Classification | T4 | ||||

| Ambient Temperature | -20°C to +40°C | ||||

| Certificate | BASEEFA Ex 78209X* | ||||

| Enclosure | Nickel Plated Brass and Gun Metal | ||||

| Lens | Ball Glass/Polycarbonate Dome | Toughened Glass (15mm) | |||

| Beam Type | All-around 360° Illumination | Flood (Matt Reflector) (as standard) or Spot (Polished Reflector) (to order) |

|||

| Light Source: | Part No. | A-129 (as std) |

A-159 (as alt) |

A-129 (as std) |

A-159 (as alt) |

| Type | Tungsten Halogen Filled Filament Bulb | ||||

| Volts | 24v | ||||

| Watts | 250w | ||||

| Output | 6000 lm | 9000 lm | 6000 lm | 9000 lm | |

| Life | 2000 hrs | 200 hrs | 2000 hrs | 200 hrs | |

| Power Source: | Type | Compressed Air Driven Turbo-alternator | |||

| Air Pressure | 4.0-8.0 bar | ||||

| Consumption | 0.75m3/min | ||||

| Ingress Protection | Once pressurised may be used underwater | ||||

| Weight | 7.9kg | 12.2kg | |||

| *Special certification conditions | A clean dry air supply must be used. Supply hose must be anti-static. | ||||

| Accessories | |

|

The Airturbo and Turbolite lighting systems are very flexible and can be adapted to all sorts of confined space applications varying from huge storage tanks to small sewers.

The Lamps can be suspended from bracing or spars, sited on platforms or mounted on tripod stands to illuminate the entry and working area as effectively as possible. As previously emphasised, there are two important conditions of Certification which must be observed in any installation: 1. The supply hose must be of an Approved Anti-Static Type such that the electrical resistance between couplings must be within the limits of 104ohms (Min.) and 108ohms (Max.) 2. The compressed air supply should be clean, dry and uncontaminated. Folding Tripod Stand A-300 Anti-Static Compressed Air Hose (A-179 and A-180) Air Line Filters Tools and Spares Repairs |